Custom CNC Machining Explained: A Buyer's Guide to Precision Manufacturing

Introduction: The Precision Imperative

"68% of engineering projects exceed timelines due to manufacturing mismatches - but the right CNC partner transforms this risk into competitive advantage."

In today's hyper-competitive industrial landscape, custom CNC machining bridges the gap between digital designs and functional precision parts. This guide decodes:

- The technical DNA of modern CNC manufacturing

- How to vet partners beyond surface-level claims

- Why ±0.01mm tolerances separate prototypes from production-grade parts

What Exactly is Custom CNC Machining?

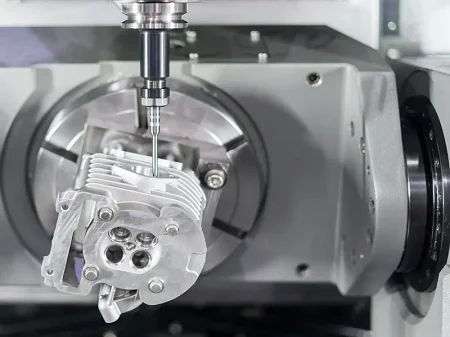

Custom CNC (Computer Numerical Control) machining involves translating digital designs into precise cutting instructions. These instructions guide automated cutting tools to shape raw materials—typically metals, plastics, or composites—into finished components with tolerances often measured in thousandths of an inch.

What sets custom CNC machining apart is the ability to create parts that aren’t feasible with standard manufacturing processes. When engineers or designers need components with specific dimensions, complex geometries, or unique features, custom CNC machining provides the solution.

Key Differentiators vs. Standard Machining

| Factor | Standard Machining | Custom CNC Machining |

|---|---|---|

| Design Flexibility | Limited to catalog items | Unlimited complex geometries |

| Precision Capability | ±0.5mm typical | ±0.01mm achievable |

| Material Options | Common alloys only | Exotics like Inconel®/PEEK® |

| Scalability | Mass production focus | Prototype ↔ Production runs |

The Technical Workflow:

- Digital Blueprint (CAD file import)

- Machine Programming (CAM software conversion)

- Precision Machining (Multi-axis toolpath execution)

- In-Process Verification (CMM/laser scanning)

- Surface Finishing (Anodizing, plating, etc.)

Industries Revolutionized by Precision CNC

1. Aerospace & Defense

- Critical Parts: Turbine blades, flight control actuators

- Standards: AS9100 compliance, ITAR certification

- Tolerance Benchmark: ≤0.025mm for aerodynamic surfaces

2. Medical Device Manufacturing

- Key Components: Orthopedic implants, surgical robots

- Validation: ISO 13485, biocompatibility testing

- Precision Demand: Micro-scale features down to 0.1mm

3. Automotive Innovation

- EV Focus: Battery enclosures, power electronics cooling

- Prototyping Speed: 5-day turnaround for test-ready parts

- Material Shift: Aluminum → Carbon fiber composites

How to Choose Your Custom CNC Manufacturing Partner

1. Technical Capability Audit

✅ Machinery: Demand 5-axis+ CNC centers (e.g., DMG Mori)

✅ Micro-Machining Proof: Request case studies with ≤0.1mm features

✅ Material Certifications: Mill certs for titanium/medical plastics

Red Flag: "We handle all materials" without material test reports

2. Quality Infrastructure

- Certifications: ISO 9001 minimum (AS9100 for aerospace)

- Metrology Tools: On-site CMMs, optical comparators

- Documentation: FAIR (First Article Inspection Reports) samples

3. Design Collaboration Process

Your ideal partner should offer:

- 24-Hour DFM Analysis: Design-for-Manufacturability feedback

- Cloud-Based Collaboration: Real-time drawing markups

- Cost Optimization History: (e.g., "Reduced client's part cost 40% via wall thickness optimization")

4. Scalability & Lead Time Transparency

| Order Type | Industry Standard | Competitive Advantage |

|---|---|---|

| Prototype (1-5) | 2-3 weeks | 5-7 business days |

| Bridge (50-500) | 6-8 weeks | 3-week guarantee |

| Rush Project | "Not possible" | 48-hour expedited |

5. Industry-Specific Experience

Ask for:

- Sector-specific case studies (medical vs. automotive differ radically)

- Compliance documentation (e.g., FDA QSR for medical devices)

- Client references in your vertical

6. Communication & Project Management Protocols

Mission-Critical Systems You Should Demand:

- Dedicated Portal Access: Real-time production tracking

- Escalation Matrix: Defined contacts for engineering/quality/scheduling emergencies

- Reporting Cadence: Daily progress updates with visual documentation (e.g., CMM scan overlays)

Case Example: Medical client avoided FDA audit failure via our real-time deviation alerts when surface finish measured Ra 0.2μm beyond spec.

7. Cost Structure Transparency

Decoding CNC Quotation Breakdown:

| Cost Driver | Industry Grey Areas | Best Practice Transparency |

|---|---|---|

| Material Markup | 80-120% hidden fee | Cost+10% certified mill rates |

| Machine Time | Bundled ambiguous hours | Per-operation time logs |

| Secondary Processing | "Misc services" line item | Anodizing/Painting per part |

| Quality Validation | Charged per "batch" | Per-part inspection reports |

Value-Optimization Tactics:

✅ Design Consolidation: Reduce part count via multi-axis machining (saves 30-50% assembly costs)

✅ Material Substitution: Aircraft-grade aluminum instead of titanium where feasible

✅ Batch Optimization: Strategic order phasing to minimize setup charges

Why Precision Demands Specialized Partners

Case Study: Drone Gimbal Mount Failure

- Client's Prior Vendor: 0.15mm tolerance (vibration caused fatigue cracks)

- Our Solution:

- Redesigned with 0.05mm concentricity tolerance

- Switched to 7075-T6 aluminum (weight/strength optimized)

- Reduced part count from 5 to 2 through multi-axis machining

- Outcome: 200K cycles without failure (validated in wind tunnel)

"Precision isn't just numbers - it's understanding how microns impact function in real-world environments."

— [Going Rapid] Lead Manufacturing Engineer

The [Going Rapid] Difference: Beyond the Machine

As an ISO 9001 & ISO 13485 custom CNC machining manufacturer, we engineer outcomes:

| Capability | Industry Standard | Our Benchmark |

|---|---|---|

| Micro-Scale Tolerance | ±0.1mm | ±0.025mm |

| Complex Geometry | 3-axis | 5+ axis simultaneous |

| Medical-Grade Surface | Ra 1.6μm | Ra 0.4μm (mirror finish) |

| Urgent Turnaround | 10+ days | 48-hour critical path |

Our Process Guarantees:

- Digital Twin Verification: All parts simulated before cutting

- In-Line Metrology: Automated inspection after every operation

- Supply Chain Control: In-house tooling/treatment to eliminate delays

Conclusion: Precision as Competitive Leverage

Choosing a custom CNC machining manufacturer transcends machine specs - it's about:

- Technical Partnership: Engineers who anticipate failure points

- Transparency: Real-time production visibility

- Accountability: Certifications backed by data

Ready to transform designs into market-ready precision?

[Request Free DFM Analysis] - Upload your CAD file for instant manufacturability feedback

[Schedule Factory Tour] - See our 5-axis CNC cells in action (On-site)

Going Rapid

Going Rapid