Precision CNC Machining Services: 3-Axis/5-Axis Milling & Turning

ISO 9001 & ISO 13485 Certified Solutions for Prototyping to Full Production

3-Axis CNC Milling Service

Our 3-axis CNC milling delivers Precision machining (±0.01mm) for aluminum, steel, and plastics. Ideal for brackets, housings, and mechanical parts. ISO-certified quality, optimized for automotive and electronics industries.

5-Axis CNC Machining Service

Advanced multi-axis precision (±0.003mm) for complex geometries in titanium, aerospace alloys, and medical-grade materials. ISO certified solutions for turbine blades, implants, and high-performance components, with mirror-finish capabilities and real-time quality monitoring

CNC Turning Service

High-precision rotational part machining (±0.005mm) for stainless steel, copper, and tool steel. Specialized in shafts, bushings, and threaded components, with live tooling options for complex geometries. ISO-certified production, surface finishes down to Ra 0.4μm, tailored for hydraulic systems and precision assemblies.

Advanced Manufacturing Technology

Offering advanced manufacturing solutions for aerospace, medical devices, and automotive systems

On-Time Project Delivery

Our global network ensures 24-48 hour expedited delivery for urgent projects

Global Manufacturing Excellence

Leveraging a worldwide network of ISO-certified facilities to ensure quality and efficiency.

Experienced Engineers

Team of expert engineers with over 15 years of experience in precision manufacturing.

Get Your CNC Parts Today?

Transform your concept into reality with our fast, precise CNC machining and production services.

Custom CNC Machining Tolerances

Whether it’s metal or plastic CNC parts. When cooperating with our TECHNOLOGY, we guarantee that all parts will be manufactured according to your specifications.

| Standard | Details |

|---|---|

Precision Tolerances | We can manufacturing and inspecting components to exacting tolerances as defined by your engineering drawings and GD&T specifications, including tolerances tighter than +/- 0.001 inches. |

Maximum Part Size | Milling: 4000 mm×1500 mm×600 mm Turning: 200 mm×500 mm |

Minimum Part Size | 1 mm×1 mm |

Minimum Feature Size | Φ 0.50 mm |

Linear Dimension | ±0.025 mm |

Tolerances | ±0.01 mm |

Shaft Diameters | ±0.025 mm |

Min Wall Thickness | 0.5mm |

Min End Mill Size | 0.5mm |

Min Drill Size | 1mm |

Min Tapped Hole Size | ±0.02 mm |

Surface Finish | Standard finish is as-machined. Additional finishing options(chromic acid anodizing, cadmium plating, copper plating, titanium anodizing ...) can be specified when getting a quote. |

| Standard Lead Time | 3 business days |

CNC Machining Materials

Our CNC machining services provide instant quotes for custom parts across 50+ certified engineering materials, including aerospace-grade metals, medical-compliant alloys, and industrial polymers. For specialized requirements, our technical team facilitates material sourcing for exotic alloys, MIL-spec composites, or custom-tempered grades, ensuring compliance with your project’s mechanical, thermal, and regulatory specifications.

All materials come with full material certification (MTC) and comply with ISO 9001:2015 quality standards

Aluminum

High strength-to-weight ratio, excellent machinability

Key Properties:

- Aircraft-grade alloys (6061-T6, 7075-T6)

- Heat treatable

- Corrosion resistant

- Excellent thermal conductivity

Stainless Steel

Superior corrosion resistance and durability

Key Properties:

- 304 & 316 grades

- Medical grade compliant

- High tensile strength

- Passivation available

Steel

Cost-effective structural solutions

Key Properties:

- Mild steel (1018, 1045)

- Pre-hardened alloys

- Excellent machinability

- Surface treatments available

Brass

Premium decorative and functional applications

Key Properties:

- Free-machining grades

- Natural corrosion resistance

- Excellent electrical conductivity

- Low friction coefficient

Copper

Optimal thermal and electrical conductivity

Key Properties:

- C110 (Electrolytic Tough Pitch)

- High purity grades

- Natural antimicrobial properties

- Excellent heat dissipation

Titanium

Exceptional strength and biocompatibility

Key Properties:

- Grade 5 (Ti-6Al-4V)

- Medical implant compliant

- High temperature resistance

- Excellent strength-to-weight ratio

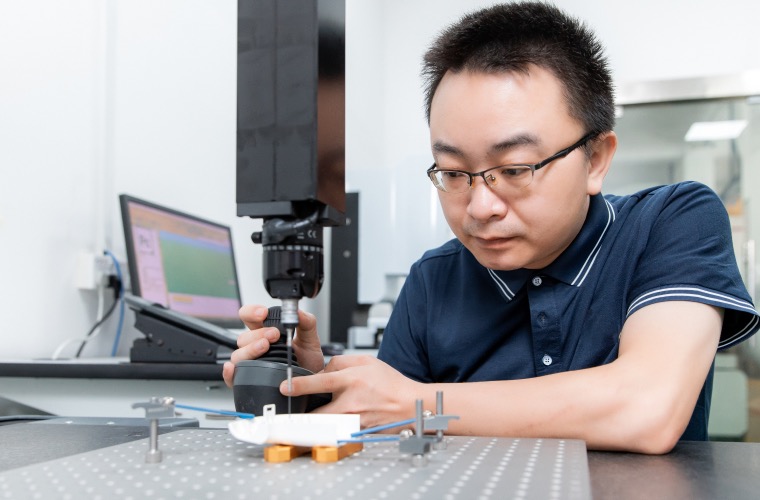

All Time High-Quality CNC Machining Service

Our machining service enforces rigorous 3-stage quality control (DFM → CMM → Certification) throughout production, achieving 99.98% first-pass yield for prototypes and final components. Every part undergoes precision validation (±0.003mm) with traceable documentation.

Our metrology lab deploys Mitutoyo CMMs (0.8μm accuracy), Olympus XRF analyzers, and surface roughness testers to scrutinize dimensions, material composition (ASTM/AMS standards), and finishes (Ra 0.05-12.5μm)

- 20+ inspection equipment including CMM and 2D measuring tools

- 30+ experienced quality engineers overseeing each project

- ISO 9001:2015 and ISO 13485 certified processes

Going Rapid

Going Rapid